Although 3D printing is still some time away from mainstream adoption, it is gathering pace - locally and internationally - with sales at South African companies doubling year-on-year; outstripping the 49% gains expected globally.

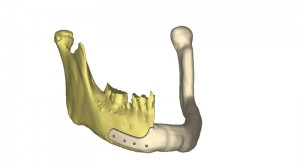

Among some of the items coming off the printing line are a locally-made titanium jaw, and internationally, items such as: titanium mesh to rebuild a skull, a vertebrae, a bicycle, guitar, flute, a car and food. Gartner lists 3D printing among its top strategic trends for next year, saying it will reach a tipping point over the next three years as the market for relatively low-cost devices continues to grow rapidly and industrial use expands significantly.

New industrial, biomedical and consumer applications will continue to demonstrate that 3D printing is a real, viable and cost-effective means to reduce costs through improved designs, streamlined prototyping and short-run manufacturing, it says.

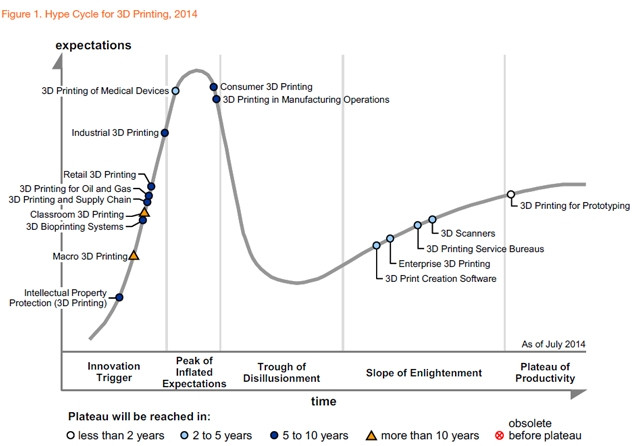

Yet, many of the solutions are still five to 10 years away from mainstream adoption, and consumer uptake will be outpaced by business and medical applications that have more compelling use cases in the short term, it says. Research VP Pete Basiliere notes about 40 manufacturers sell the 3D printers most commonly used in businesses, and over 200 start-ups worldwide are developing and selling consumer-oriented 3D printers, priced from just a few hundred dollars. "However, even this price is too high for mainstream consumers at this time, despite broad awareness of the technology and considerable media interest."

In two to five years, there will be greater adoption of enterprise 3D printing, nurtured in part by the continued acceptance and use of 3D print creation software, 3D scanners and 3D printing service bureaus, says Gartner. "At around this time, 3D printing of medical devices will offer exciting, life-altering benefits that will result in global use of 3D printing technology for prosthetics and implants," adds Basiliere. However, macro 3D printing of large structures and classroom 3D printing are more than 10 years away from mainstream adoption.

A must have

Locally, interest is picking up and the device has also found a neat role in medical use. Helen von Maltitz, a director at 3D Printing Systems, says the company - currently in build-up phase - has seen sales double year-on-year, and has so far sold around 300 of the machines. She adds that prices of the devices, especially the smaller makes, have come down, despite the weakness of the rand, with desktop machines now at around $10 000, and larger printers at around $24 000.

Von Maltitz notes universities are using the machines for training, especially in areas such as industrial design, and fine arts. "You can modularise your designs." Other uses include toys, moulding and prototypes, she adds.

People also buy printers because "they just want to have one," says Von Maltitz, adding some use them to run small businesses printing items for others. She sees demand picking up, especially as templates move towards becoming customisable.

However, as printing takes between one-and-a-half to four hours, the technology is more suited to once-off or low volume items, such as spare parts for car dealers, explains Von Maltitz. She notes the tech has particularly come to the fore in the medical industry.

A few months ago, Cules van den Heever, extraordinary professor at the Central University of Technology (CUT) from the University of Pretoria, and CUT's Centre for Rapid Prototyping and Manufacturing played a role in transplanting jaws for two patients who had lost much of their jawline because of cancer and other related diseases.

Together with two other surgeons and two dentists, Van den Heever implanted jaws made out of titanium, which had been printed at CUT's Bloemfontein campus. In a statement, CUT noted "this is ground-breaking work in 3D printing in the medical field".

Rapid 3D Printing member David Bullock says the company, which has been around since "the beginning" in 2004, has seen rapid growth in the past three years, with sales doubling each year. He notes the market is becoming more competitive, with many small players entering, although some levels of saturation are being seen.

3D printing offers "huge potential," says Bullock, adding the tools are being used in sectors such as jewellery and manufacturing, while the consumer segment is becoming quite big. He notes 3D printing's potential lies in "places where it is providing real world solutions".

The sector, currently at hype point based on Gartner's hype cycle, was worth around R200 million last year, although this "dramatic" year-on-year jump included investments of around R80 million by universities, says Bullock.

Share