Johannesburg, 10 Nov 2017

Modular freestanding enclosures offer a number of key advantages when compared to traditional unibody enclosures. Many times these attributes are overlooked either out of a false perception of increased enclosure costs, reluctance to change, or a simple lack of awareness to the possible benefits of modular solutions.

This white paper seeks to provide a more clear understanding, for designers, integrators and end users alike, of the benefits offered by modular enclosures. Examples will be made to demonstrate the savings that can be realised over the lifespan of an enclosure after factoring in common use and operating costs such as maintenance, modifications and expansions associated with typical industrial applications.

Definition of modularity

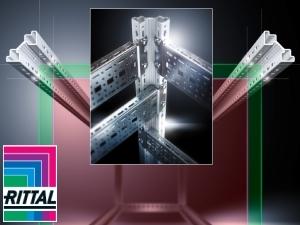

The strength (both literally and figuratively) of a modular enclosure lies with its frame. The frame consists of metal forms with a series of holes spaced at standardised units of dimensions such that common accessories can be added to the interior without drilling or welding. Multiple frames can be joined together (side-to-side, back-to-back, side-to-back, top-to-bottom, etc.) to create infinite configurations. This flexible arrangement is accompanied by an ease of use. Conversely, traditional unibody enclosures are folded sheets of metal with welded seams designed for singular use. Changes are very difficult without costly fabrication techniques.

Share