Making use of locally manufactured thermoplastic components and engineering expertise, a broadband fibre optic connectivity system was designed and built to cater for the city of Cape Town's increasing communications requirements.

Raison d'etre

Social demands for increased municipal services has had an equal demand effect for basic domestic, industrial and business services from the city of Cape Town, says Alan Nelson of Tank Industries.

The need for faster and improved communications to cater for increased capacity in the network, had become a matter of urgency. The choice for upgrading the system was to change over from the conventional FO cable interconnecting method, to a blown fibre optic (BFO) cable into a broadband system.

Prototype Design Preparation

The project was started way back in 2007, when a decision was made by COCT engineers to use blown fibre optic (BFO) instead of a conventional FO cable, for their new communications network. Following initial design requirement meetings with the COCT Consultants and Communications Engineers, a site meeting was held to determine if the Tank Industries proposed System Configuration, would meet the fitment requirements of the "Rocha" manhole design. A simulated Rocha manhole was constructed of wood and polystyrene materials in the Tank Industries Test Laboratory, and fitted with Blown FO Cables, supplied by the Consultants.

Prototype Preparation

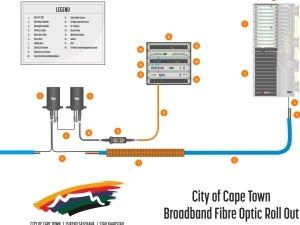

The prototype Tank design proposal was for a 96 Fibre "Core Closure" and a 24 Fibre "Access Closure" (Refer figure 1) interconnected to a R&M ODF and an R&M patch panel distribution unit respectively. Following a few design changes, a decision was reached to manufacture two samples for testing; one in the laboratories for specification testing and the second in the field, to ensure performance parameters were met. (Refer testing methods).

Dome closure configurations

The 144 FO core closure is the main feed for the system. It is a moulded "Dome" shaped outer shell with a moulded base housing a 144 FO organiser management system. Fibre splices are protected by way of silicone heat-shrinkable tubes with a stainless steel rod inserted between the tubes for mechanical strength, these are supported in FO splice protector holders. A moulded swing clamp with an "O" ring, holds and seals the two substructures together

Two oval ports and six PMA polyamide conduits are sealed into the base for FO cable entry and exit.

The 48 FO Access Closure is manufactured to the same design as the FO Core Closure but varies in FO management capacity. Various entry points to accommodate individual customers/users are provided e.g. billing, metering departments, internal and external data users.

The core closure has a direct FO tube to FO tray system where as the access closure has a tubeless fibre management system, which allows for easy distribution of fibres between the trays, and controlled distribution of fibres to the clients.

Ancillaries

Fibre optic coil boxes are utilised to store all excess FO cables in the manholes. The FO cable is coiled, placed and secured into the coil box.

Other accessories include LC-APC pigtails, adaptors and patch cords for installation into the various switching centres. Five switch centres have been built by the COCT, amongst them are the main centres of Gallows Hill, Athlone, Parow and Bellville. All centres are in full operation and functioning to Customer expectations.

Test and Evaluation

Performance testing for configuration, fitment and interchangeability, was carried out in a Rocla manhole at Blackheath Cape Town. The system met all the specifications and customer requirements.

Environmental testing was carried out in the Tank Industries' laboratory in Retreat Cape Town, and consisted of testing the Dome to BT-LN 450 B( air tightness) ingress protection to IP 68, temperature cycling, impact testing( ASTM G 53), the base material to ISO 846 Method A, and the total assembled product to Bellcore specification GR - 771, water submersion test. All tests passed.

Summary

The demand for high technology communications systems are ever increasing in our modern society. The presence of excellent design engineers from the city of Cape Town, and locally manufactured interconnecting FO cable accessories by Tank Industries, to meet these new demands, is a credit to the skills capabilities in South Africa.

Acknowledgement

Tank Industries wishes to thank the Messer's, Sybrand Brink, Fredel van As and Noel van Zyl for their proactive participation in the project, and the city of Cape Town engineers, for their trust and support during the design, manufacture, testing and installation phases.

Share

Editorial contacts