Lance Zikalala, MD of nCoded Solutions, delivered a lecture at the Manufacturing Technologies and Operational Excellence Conference in late June 2017.

Held at the Balalaika Hotel in Sandton City, Johannesburg, the conference was a great success, pulling together key leaders and decision-makers; from government and manufacturing.

nCoded Solutions was invited to share its thoughts about Designing Business Operations for Operational Excellence.

Zikalala began his lecture by pointing out the significance and timely nature of his discussion. For this purpose, he referred to the challenges facing the manufacturing sector in South Africa these days. He emphasised that he is in agreement with many of the initiatives that many productivity improvement organisations try to promote - but the pace was much too slow.

Many organisations are faced with growing competitive pressures and must improve their operational performance in the face of continuous change in business and technological environments in order to succeed.

Zikalala explained and pointed out what is happening now: (i) Manufacturing growth is on the decline; (ii) Business is uncertain about the future; (iii) There is anxiety about the recession; and (iv) Politics are also a major concern.

When businesses are uncertain, they change. Businesses do not like anxiety, Zikalala said. They reduce waste, they reduce spending, and they stop hiring. Despite these uncertainties, something interesting is happening. Organisations are moving towards technology.

Many technologies have been deployed over the years to improve productivity, quality and throughput in manufacturing and other distributed systems. Machine automation systems, process control systems, and building automation systems have been deployed widely over recent decades; much of it since the 1990s, based on computer-controlled systems that were based on proprietary technologies optimised for the subsystem.

At the business system level, we have seen wide adoption of software to manage the financial and transactional elements of business. From customer relations management to enterprise resource planning to supply chain management to quality improvement, software systems are used everywhere.

Yet when we look at these systems we find that, in many cases, they remain disconnected from one another, many with proprietary communication protocols that make coordination difficult.

As companies seek the next level of business performance, they must seek to improve their operational efficiency and coordination with business objectives.

Zikalala continued to explain that all companies have their own unique situations, based on their own evolutions and market realities, but all of them have one thing in common: better coordination between business systems and production operations that would result in improved overall performance.

Today's operations are an amalgamation of manual and automated systems. The processes and procedures between demand and supply for any operations are many fold and complex.

Strategies to improve operations have evolved over the years, and have come under various initiatives defined in different ways under various and different names. Names such as:

* Quality improvement;

* Business process reengineering;

* Cost reduction;

* TCO reduction;

* Reliability improvement;

* Downtime reduction;

* Six Sigma;

* Investment at the business layer in ERP systems;

* Focus on supply chain; and

* On e-business, etc.

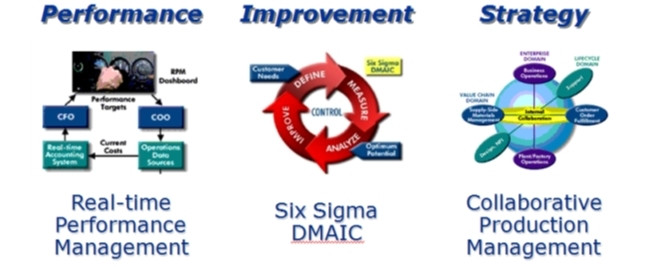

Three concepts continue to stand out as strategies for achieving operational excellence, around the areas of performance, improvement and strategy:

Performance: real-time performance management (RPM), which provides a business context to production operations through visibility of "key performance indicators" as they are happening, so that operations can be optimised around business needs, and operational issues can be corrected before they become financial ones.

Improvement: quality programs employing Six Sigma methods using the DMAIC model for continuous improvement. The DMAIC model is a structured process of defining, measuring, analysing, improving and controlling production to achieve a very low level of defects ... approaching the statistical six standard deviations (Sigmas) from the norm, which implies 3.2 defects per million opportunities, an admirable objective for many operations.

Strategy: collaborative production management (CPM) is an architecture that most efficiently connects multiple axes of a production operation as efficiently as possible through automation. Business operations are connected to plant operations, design, support, supply and customer systems in ways that minimise the effort and maximise the value between each area of the operation.

Zikalala concluded by saying that manufacturers should consider utilising manufacturing intelligence for real-time data collection and connectivity at the shop floor, establishing operational context and exposing manufacturing information to the rest of the enterprise.

With a very simple approach and adoption of open standards, users can achieve maximum integration and reap the great benefits of operational excellence.

Acknowledgements

* Dr. Habib Rehman.

* Russell Desjarlais.

* Mark Hepburn.

* ICONICS.

Share

Editorial contacts